Pressure Regulators; Unloaders; Relief/Pop-Off Valves; Pulsation Dampeners; Pressure Gauges; Thermal Valves; Inlet Pressure Stabilizers; Jetters; Pulse Pumps; Inlet Filter; Guns; Lances/Nozzles; Bell Housings; Service Tools Available Models)

CAT Triplex/Plunger Pumps are high-performance, precision-engineered pumps widely recognized for their durability, reliability, and efficiency. Manufactured by CAT Pumps, these triplex plunger pumps are designed to handle a variety of demanding applications, delivering consistent performance and extended service life. They are suitable for industries requiring high-pressure pumping solutions, such as car washes, reverse osmosis, pressure washing, and industrial cleaning.

Durability: CAT Triplex/Plunger Pumps are constructed from high-quality materials, including brass, stainless steel, and anodized aluminum. These materials ensure excellent resistance to corrosion and wear, providing longevity even in harsh environments.

Efficiency: These pumps are designed for optimal efficiency, featuring high volumetric and mechanical efficiency. Their precise engineering ensures minimal energy loss, making them cost-effective for continuous operation.

Performance: CAT Plunger Pumps deliver high-pressure capabilities, ranging from 100 to over 10,000 PSI. This makes them suitable for various applications requiring consistent and powerful performance.

Maintenance: Designed for easy maintenance, CAT Pumps feature a simple, modular design. This allows for straightforward servicing and replacement of components, reducing downtime and maintenance costs.

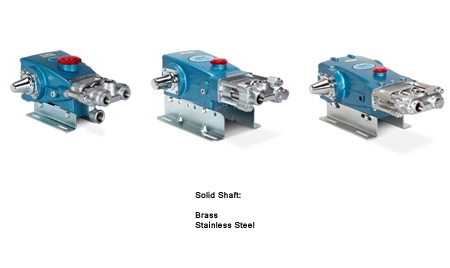

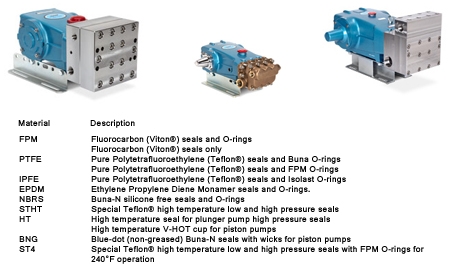

Cat Pumps high temperature pumps can handle liquids up to 200°F/93.3°C and perform in intermittent run-dry conditions. Flow range of 0.5 to 20 gpm/1.9 to 75.7 lpm and a pressure range of 100 to 3500 psi/6.9 to 241.5 bar. Available in brass, nickel aluminum bronze and stainless steel to cover a wide variety of applications.

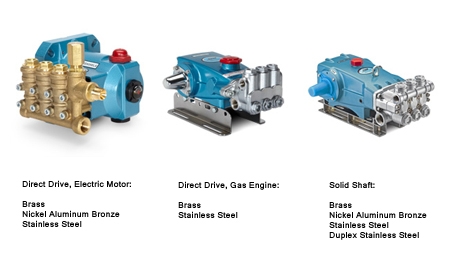

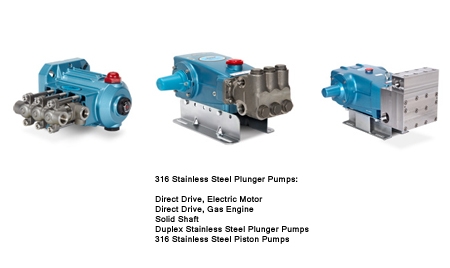

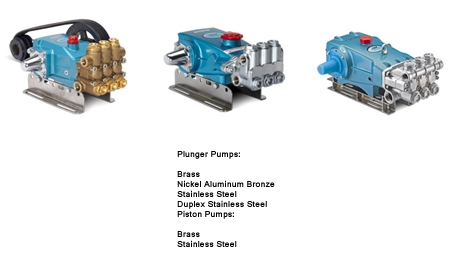

Cat Pumps high-pressure plunger pumps are industry recognized as the longest-lasting, most reliable pumps available. Cat Pumps designs and builds products to the highest quality level for one important reason: our customers depend on our products to keep their equipment running. Plunger pump performance range is 0.13 gpm to 240 gpm (0.49 to 908 lpm) and 100 psi to 10,000 psi (6.9 bar to 689 bar). Pumps are available in brass, nickel aluminum bronze, 304 and 316 stainless steel, and duplex stainless steel. Pump drives include electric motor, gas/diesel engine, hydraulic, and pneumatic

Cat Pumps high-pressure piston pumps are industry recognized as the longest-lasting, most reliable pumps available. Cat Pumps designs and builds products to the highest quality level for one important reason: our customers depend on our products to keep their equipment running. Piston pump performance range is 3.0 gpm to 60 gpm (11.3 to 227 lpm) and 100 psi to 1,500 psi (6.9 to 103 bar). Piston pumps exhibit excellent suction capability, often not requiring flooded suction or booster pumps. Pumps are available with brass and 316 stainless steel manifolds and 304 stainless valve components.

Cat Pumps gearbox pumps are direct-drive high-pressure pumps that can be easily mounted on standard gas or diesel engines up to 24 horsepower. The gearbox drive has a 2 to 1 ratio allowing the pump to run at half the speed of the engine. This configuration provides a compact assembly without running the pump at high engine RPM. The gearbox is completely sealed, offering protection against rain, dust, and humidity. Cat Pumps gearbox pumps are #1 in commercial-duty pressure washers due to superior product life and ability to perform well in continuous duty use.

Cat Pumps offers a complete line of nickel aluminum bronze pumps to meet industry demands. These pumps are frequently found in oilfield and reverse osmosis applications throughout the world. The superior strength and corrosion-resistance of nickel aluminum bronze, combined with Cat Pumps’ dependability, makes them an industry-leading choice. Nickel aluminum bronze pumps are stock items at Cat Pumps. A wide variety of flow and pressure ranges are available: 0.13 – 75 GPM, and 100 – 5,000 PSI.

Cat Pumps offers a complete line of stainless steel pumps to meet the demands of many industrial applications. Available as 304, 316 and duplex stainless steel, these pumps are stock items at Cat Pumps and offer a wide variety of flow and pressure ranges: 0.13 – 240 GPM, and 100 – 10,000 PSI. The stainless steel pumps offer superior corrosion resistance, strength and long life in the applications where aggressive liquids are being pumped.

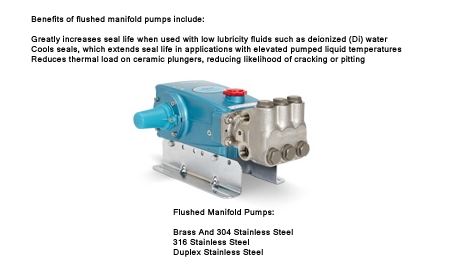

Like all standard plunger pumps, a flushed manifold pump is configured with an inlet and outlet port. However, on a flushed manifold pump, the manifold is also designed with an inlet and outlet flushing port to circulate liquid between the high pressure and low pressure seals to extend seal life and reduce pump maintenance. Cat Pumps offers a broad performance range of flushed manifold pumps from 3.0 to 240.0 gpm (15 to 908 lpm) and up to 10,000 psi (689 bar)

Cat Pumps’ direct-drive pumps offer a compact and cost-effective pump mounting, and are available for electric and engine drives. This option allows for easy installation with the pump mounting directly to the motor or engine. For electric motor direct-drive pumps there are two options available: hollow shaft pumps and bell housing. The hollow shaft pumps fit 56C or 184TC face motors and will bolt directly to the unit. The bell housing mount utilizes a flex coupler between the pump and motor shafts, and the bell housing mounts the pump to the motor. Bell housing direct-drive pumps are commonly used up to 15 HP. For engine direct-drive pumps there are two options available: hollow shaft pumps and gearbox pumps. Both options bolt directly to the engine, but the gearbox version allows the pump to run at half the speed of the engine.

Cat Pumps offers a range of belt-driven pumps from 0.13 GPM up to 240 GPM. Belt-drive is a very popular option because of the flow flexibility given within pulley ratios. Using a belt-drive isolates the pump from the heat and vibration of the motor or engine driving the pump. The belt also isolates shock from an engine or motor on start up, which can put excess wear on the crankshaft and drive end components. Belt-drive pumps give the flexibility of changing pump flow by a simple pulley change. Belt-driven pumps are available in brass, nickel aluminum bronze and stainless steel with a wide range of flow and pressures: 0.13 – 240 GPM, and 100 – 10,000 PSI. Complete drive packages (pulleys, hubs, keys and belts) are available for all of our pumps. For assistance in sizing drive packages

For pumping applications located in potentially explosive atmospheres, Cat Pumps offers a complete line of pumps that meet the ATEX 2 directive for such environments. Pump compliance to the ATEX directives is common in industries such as petrochemical, chemical, oil & gas, and bio-fuels. Under the appropriate ATEX directive, equipment is designated by group, category and zone. Cat Pumps has been certified as ATEX 2 compliant, which also covers the ATEX 3 requirements. All Cat Pump models (excluding gearbox driven) in the following frame sizes are compliant with the ATEX directive for Group 2, Category 2 and Zones 1 and 2 (Group 2 includes Zone G)

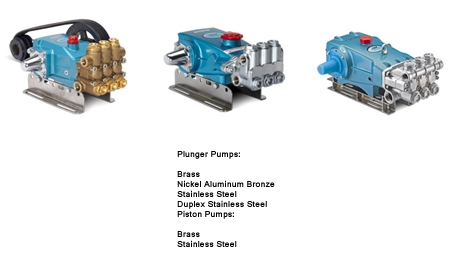

Cat Pumps offers a wide selection of elastomers and manifold materials to meet a large variety of chemical application needs. Cat Pumps products work best with fluids with a pH level between 5 and 9 and a viscosity less than 500 cP (centipoises). Please contact our technical support team for selection assistance If you are working outside of these ranges

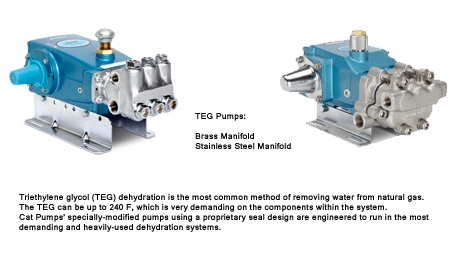

Cat Pumps has spent years working with engineers and maintenance professionals in the natural gas industry to develop the best solution for the TEG dehydration application. After extensive research & development and field testing, Cat Pumps launched this industry-changing product the first quarter of 2011. The product line is expanding to meet the variety of demands for TEG Dehydration. Pumps are readily available for 0.5 – 25 GPM and can be fitted with brass or 316 stainless steel manifolds. A full-line of product accessories are available and pumps can be built into a custom-engineered system.