PT. TIRTA SURYA MANDIRI

Nagara AODD Pump

Nagara AODD (Air-Operated Double Diaphragm) Pumps are well-regarded for their robust performance, reliability, and versatility in various fluid handling applications. Designed to handle a wide range of fluids, from water to highly viscous, abrasive, and chemically aggressive substances, these pumps are used across many industries, including chemical processing, wastewater treatment, food and beverage, and more. Their air-operated design makes them safe for use in hazardous environments where electricity could pose a risk.

Air-Operated Design: Nagara AODD pumps are powered by compressed air, making them suitable for use in environments where electrical pumps may be hazardous. This feature also allows for easy operation and control of flow rates.

Versatility: These pumps can handle a diverse array of fluids, including corrosive chemicals, abrasive slurries, high-viscosity liquids, and shear-sensitive materials. This versatility makes them suitable for a wide range of industrial applications.

Self-Priming and Dry Running: Nagara pumps are self-priming, capable of handling high suction lifts, and can run dry without damage, providing flexibility and reliability in various operating conditions.

Leak-Free Operation: The design of Nagara AODD pumps ensures leak-free operation, which is crucial when handling hazardous or valuable fluids. This feature enhances safety and minimizes environmental risks.

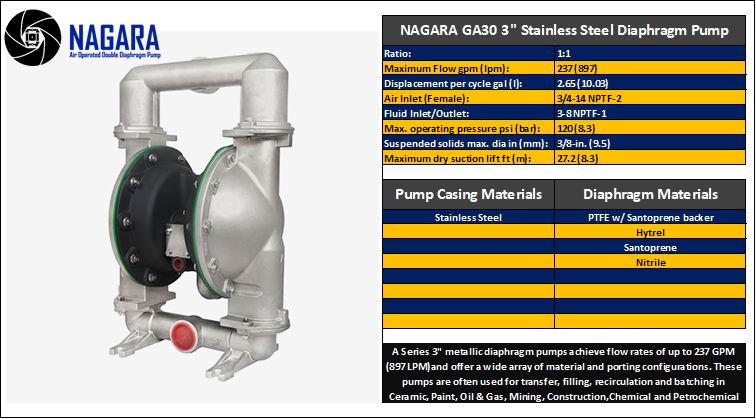

GA30 Stainless Steel

Series 3" metallic (Stainless Steel) diaphragm pumps achieve flow rates up to 237 GPM (897 LPM) and offer various material and porting configurations. Ideal for transfer, filling, recirculation, and batching in Ceramic, Paint, Oil & Gas, Mining, Construction, Chemical, and Petrochemical industries.

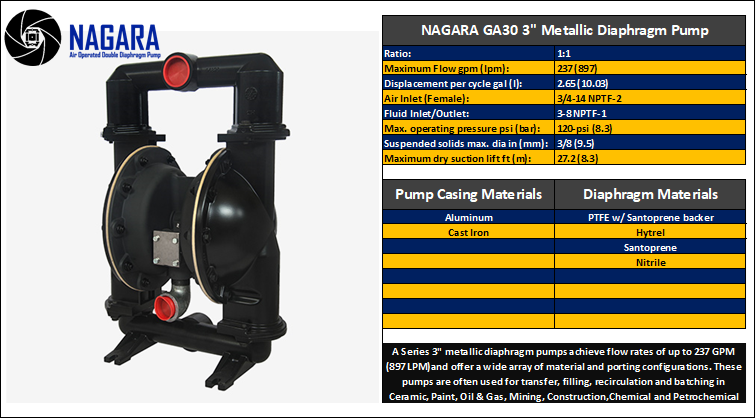

GA30 Metallic

Series 3" metallic (Aluminium & Cast Iron) diaphragm pumps achieve flow rates up to 237 GPM (897 LPM) and offer various material and porting configurations. Ideal for transfer, filling, recirculation, and batching in Ceramic, Paint, Oil & Gas, Mining, Construction, Chemical, and Petrochemical industries.

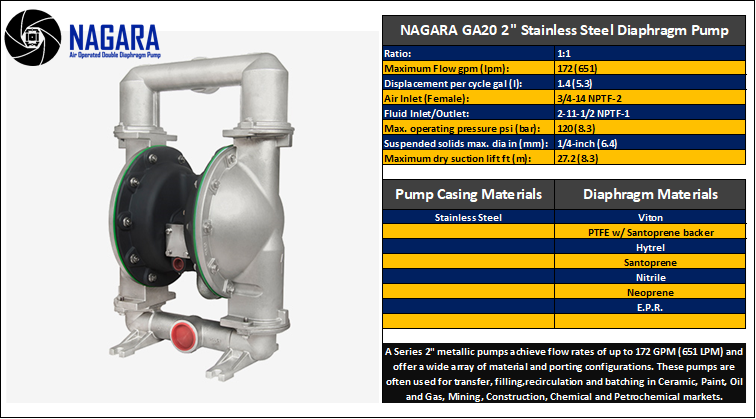

GA20 Stainless Steel

Series 2" metallic (Stainless Steel) pumps achieve flow rates up to 172 GPM (651 LPM) and offer various material and porting configurations. Ideal for transfer, filling, recirculation, and batching in Ceramic, Paint, Oil & Gas, Mining, Construction, Chemical, and Petrochemical industries.

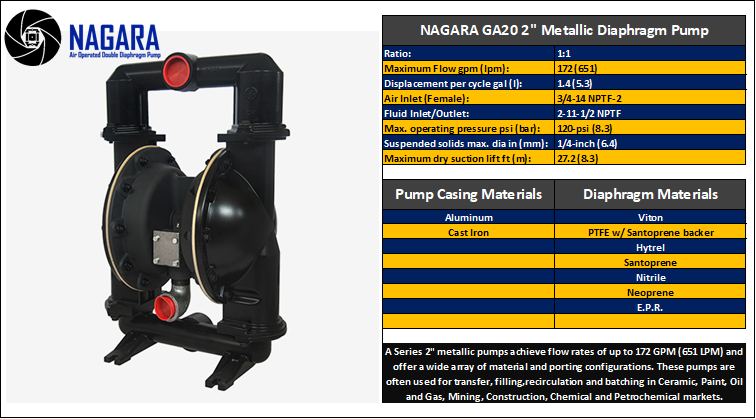

GA20 Metallic

Series 2" metallic (Aluminium & Cast Iron) pumps achieve flow rates up to 172 GPM (651 LPM) and offer various material and porting configurations. These pumps are ideal for transfer, filling, recirculation, and batching in Ceramic, Paint, Oil & Gas, Mining, Construction, Chemical, and Petrochemical markets.

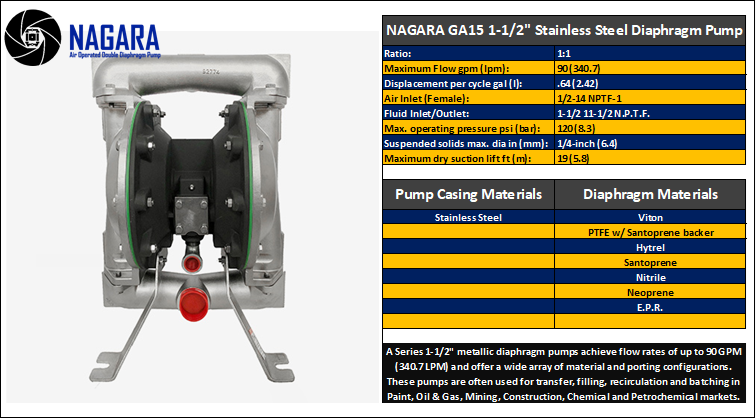

GA15 Stainless Steel

Series 1-1/2" metallic (Stainless Steel) diaphragm pumps achieve flow rates up to 90 GPM (340.7 LPM) and offer various material and porting configurations. These pumps are ideal for transfer, filling, recirculation, and batching in Paint, Oil & Gas, Mining, Construction, Chemical, and Petrochemical markets.

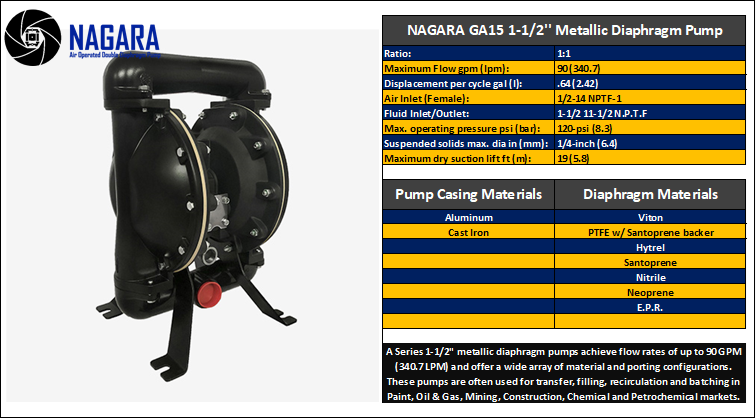

GA15 Metallic

Series 1-1/2" metallic (Aluminium & Cast Iron) diaphragm pumps achieve flow rates up to 90 GPM (340.7 LPM) and offer various material and porting configurations. These pumps are ideal for transfer, filling, recirculation, and batching in Paint, Oil & Gas, Mining, Construction, Chemical, and Petrochemical markets.

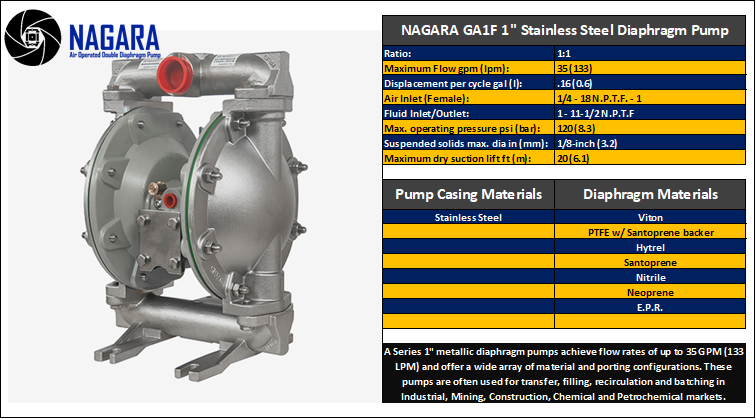

GA1F Stainless Steel

Series 1" metallic (Stainless Steel) diaphragm pumps achieve flow rates up to 35 GPM (133 LPM) and offer various material and porting configurations. These pumps are commonly used for transfer, filling, recirculation, and batching in Industrial, Mining, Construction, Chemical, and Petrochemical markets.

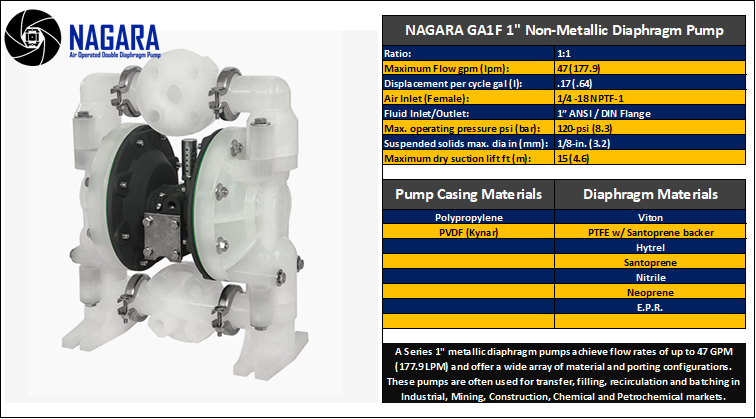

GA1F Metallic

Series 1" metallic (Aluminium & Cast Iron) diaphragm pumps achieve flow rates up to 35 GPM (133 LPM) and offer various material and porting configurations. They are commonly used for transfer, filling, recirculation, and batching in Industrial, Mining, Construction, Chemical, and Petrochemical markets.